Peculiarities of new Forms of PG

Experimental confirmation of the structural differences

of the PG forms was given by Atomic Force Microscopy

PG - Form

Grain boudaries

Steps

(broken carbon planes on a basal surface)

Traces of defects attributed to interlayer binding

The number of defects in the visual

field of 10x10 μm² of Atomic-force

microscope (averaged by 30 photos for

HAPG and by 10 photos for other materials).

(the results are kindly provided by our dealer www.nanoscopy.ru )

Defects in the honeycomb graphite structure

corresponds usually to carbon atoms in sp³ hybridization.

Such defects, as well as grain boundaries, anchor carbon planes.

It is clearly seen from the table, where the number of interlayer

defects and grain boundaries correlates with the number of broken carbon

planes on the basal surface of a sample. The defects and grain boundaries

supply the crystal with the rigidity . As the result, forms with fewer defects

and larger grains (HAPG and HOPG-flex) have flexible films used for manufacturing

of Graphite Optics.

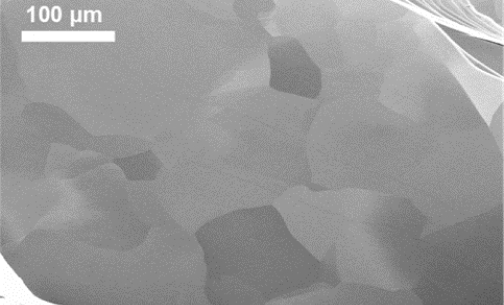

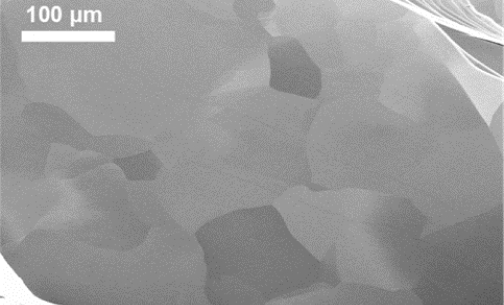

Direct methods also confirm that the size of grains and crystallite in

HOPG-flex and HAPG is several times larger that for HOPG.

Electron Microscopy (SEM) fresh HAPG surface

Back Scattering Diffraction (EBSD) ofs fresh HAPG surface

Physical Properties

of Well-Aligned PG

The physical properties of all well-aligned PG forms are quite similar. Due to the layered structure, they all are very anisotropic. They have excellent thermal conductivity in the basal plane, and rather moderate value in the perpendicular direction. Pyrolytic graphite is electrically conductive in the basal plane and insulating in the perpendicular direction.

The most investigated form is bulk HOPG, which has been on the market for over 50 year. The main physical characteristics (at 20ºC) of bulk HOPG are summarized in the Table

Physical characteristics

Value

interlayer distance (002)

3.354-3.358 Å

thermal conductivity parallel (002)

1700±100 W/(m·K)

thermal conductivity perpendicular (002)

8 ± 1 W/(m·K)

thermal expansion parallel (002)

-1 x 10-6 K -1

thermal expansion perpendicular (002)

20 x 10-6 K -1

electrical conductivity parallel (002)

2.1±0.1 x 106 [(Ω·m)-1]

electrical conductivity perpendicular (002)

5 x 102 [(Ω·m)-1]

Table physical characteristics (at 20ºC) of bulk HOPG

Decreased defect content shifts the properties of flexible forms of well-aligned PG toward ideal graphite: thermal conductivity

of HAPG is larger than that of bulk HOPG (2000±100 W/mK compared to 1700±100 W/mK) and the interlayer distance is smaller (3.354 Å instead of 3.357 Å).

The manufacturing process itself purifies the material, and all forms of well-aligned PG contain extremely low total impurities, not exceeding a few ppm. No additional cleaning procedures are required.