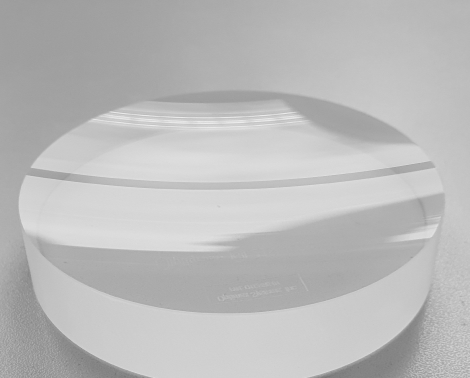

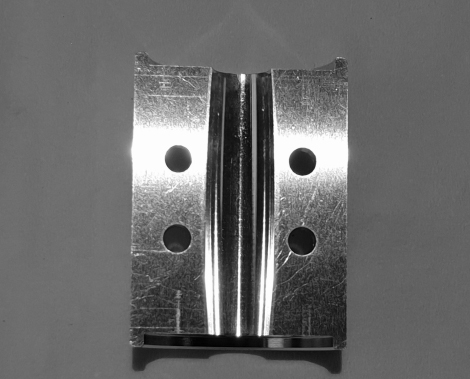

Graphite Optics

Graphite optics combines high reflectivity of graphite with the required focusing shape. High stability makes it useful for harsh environments.

Detail information about

Graphite Optics see at the following pages.